Honing or Grinding?

Choosing the Right Finishing Process for Your Needs in Modern Manufacturing

Honing and grinding are both abrasive machining processes used to improve the surface finish and dimensional accuracy of metal parts, but they differ in terms of their techniques, goals, and outcomes.

Purpose and Process

Grinding is a material removal process that involves using abrasive particles (such as grains of abrasive material like aluminum oxide or silicon carbide) to remove excess material from a workpiece. It is typically used for heavy material removal, shaping, and achieving tight tolerances and a smooth finish.

Honing is a finishing process used to improve the surface texture, roundness, and dimensional accuracy of a part under constant surface contact with the tool. It involves the use of abrasive stones or diamond hones that rotate and reciprocate within a bore or on a surface. Honing is primarily used for achieving a smoother, more precise surface finish without significant material removal.

Material Removal

Grinding is an aggressive material removal process. It removes relatively large amounts of material quickly and is suitable for tasks like stock removal and shaping. Grinding can achieve very high levels of dimensional accuracy and surface finish, making it suitable for critical applications.

Honing is a gentle material removal process. It removes only a small amount of material at a time and is designed to improve the surface finish and geometry of the workpiece without altering its dimensions significantly.

Surface Finish

Depending on the nature of the Grinding process, you could either have a rough or smooth surface. Grinding can create intricate profiles and contours that might be challenging with other machining methods. Applications can include:

- Slitting & parting

- Surface finishing

- Deburring & descaling

- Abrasive milling

- Finishing cylindrical and flat surface

- Grinding of various tools and cutters

Honing is primarily used to improve the geometric form of a surface, but can also improve the surface finish. Honing is used in applications where achieving a high-quality, internal surface finish and precise dimensions are essential, such as in engine cylinder bores, hydraulic cylinders, and gears.

The choice between these processes depends on the specific requirements of the part and the desired surface finish and dimensional accuracy. No matter what your requirements might be, Hardinge will have either a Honing or Grinding machine for your finishing process. Our Sales and Application Engineers are here to help you answer any questions you may have.

Visit Hardinge.com for more information or to contact us on a specific machine.

CNC Machining Blog

Types of Honing Machines

The need for the different types of components and tools for the machining process led to manufacturing of different types of honing machines. Honing process is used to improve the shape, precision, and surface finish of the metal workpiece.

As the dimensional and geometrical accuracy needs of workpieces vary, different types of honing machines with various types of tools are used.

Generally there are only two main types of honing machines:

• Vertical Honing Machines

• Horizontal Honing Machines

Honing is a process where with the help of abrasive scrubbing against the metal work piece the material is removed with a honing tool or stone. In order to produce precise components and machining parts of accurate geometrical shape and smooth surface texture different variations are made in the honing machines. This has resulted in variation into the parts and types of honing machines.

Honing Process

Honing process is used for precision surfacing after drilling and boring process. It is considered to be one of the best technologies used for finishing technology in manufacturing. For the purpose of removing the material from the barrel the internal honing process is used. The honing stone is made up of different types of natural and artificial abrasives. The types of abrasives used in bores are as follows:

Natural Abrasives:

• Diamond

• Corundum

• Garnet Quartz

• Other similar types of materials found in the earth

Artificial Abrasives:

• Silicon carbide

• Boron carbide

• Aluminum oxide

• Other types of aluminas

The call regarding the selection of the type of abrasive depends on the material of the metal workpiece.

Types Of Honing

Honing is classified into two types according to its functions:

Manual Honing -

The honing stone or tool rotates continuously and with hand, a metal workpiece is moved in up and down motion.

Machine Honing -

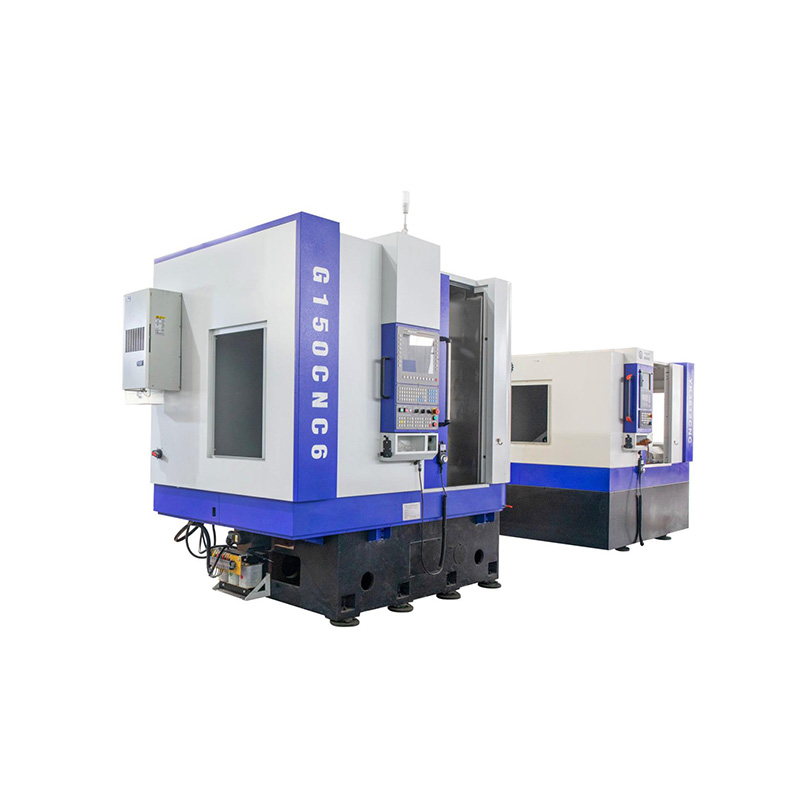

The honing stone rotates automatically as programmed for the honing process. There is no need for manually operating the machine. The operator only gives a set of commands to the CNC machines to perform a certain machining task. There are mainly two types of honing machines: Vertical honing and horizontal honing.

Advantages Of CNC Honing Machines

Here are some of the advantages mentioned to convey why machines honing has replaced the manual honing:

• Less complex fixtures

• Accurate geometrical shapes are delivered

• Precise finishing of the texture

• Efficient in finishing hard materials too

I hope you must have understood everything about the honing process. The types, advantages, functions and features of honing have been clearly described above. We can now move towards understanding what are the types of honing machines. The basic differentiating factors are some components, controls or tools that differentiate one from another.

Types Of Honing Machines

Below we have listed some types of CNC honing machines manufactured at Khushbu India. It is one of the leading Honing Machine manufacturers in India. Therefore the majorly used honing machines are listed below:

Single Pass Honing Machine

Single pass honing is used to hone a straight and un-tapered bore. The honing stone or tool is passed only once through the bore for forming a cylindrical shape or barrel. This type of honing process is useful for the internal long stroke honing. With single pass honing machines a high level of production can be achieved as multiple spindles are used for honing. Mostly for single pass honing diamond or CBN abrasive impregnated tools are used for the honing process. This type of honing machine is used for manufacturing of gears, rocker arms, gear shifter fork, gun barrel, etc.