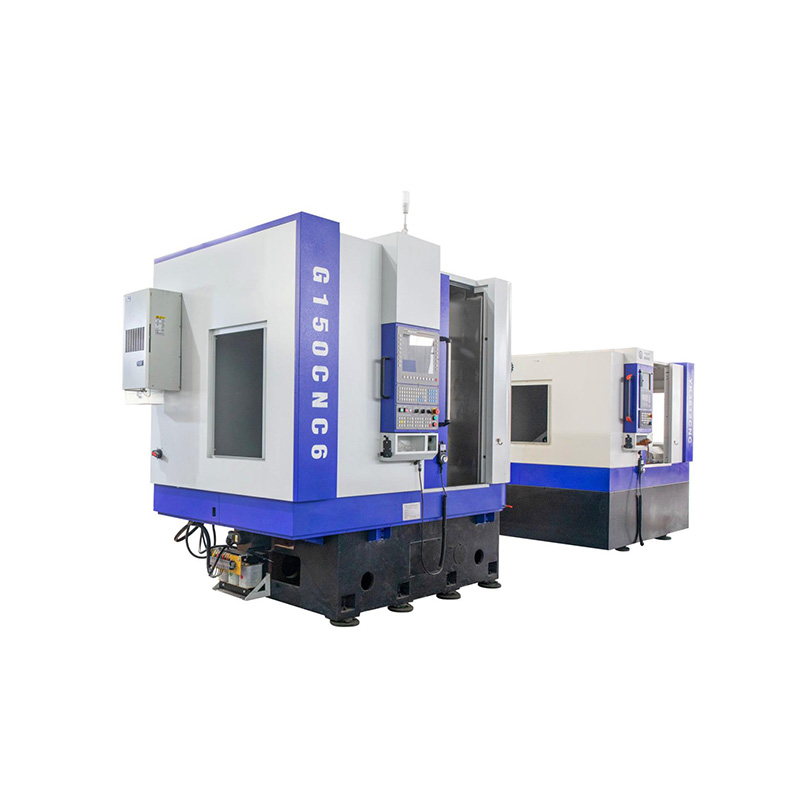

The CNC gear hobbing machine stands as a pinnacle in precision engineering, revolutionizing the production of gears. This article delves into the diverse applications of CNC gear hobbing machines, showcasing their integral role in various industries.

1. Automotive Industry: Gear Manufacturing for Vehicles

- CNC gear hobbing machines play a crucial role in crafting gears for automobiles.

- Precision is paramount in ensuring smooth transmission and optimal vehicle performance.

2. Aerospace Engineering: Precision Gears for High-Flying Machines

- In the aerospace sector, CNC gear hobbing ensures the fabrication of gears used in aircraft engines and navigation systems.

- The reliability of these gears is essential for the safety and functionality of airborne vehicles.

3. Heavy Machinery and Equipment: Power Transmission Components

- Industries relying on heavy machinery, such as construction and mining, utilize gears manufactured by CNC gear hobbing machines.

- These gears withstand rigorous conditions, facilitating the efficient operation of heavy equipment.

4. Renewable Energy: Gearing Up for Sustainability

- CNC gear hobbing machines contribute to the renewable energy sector by producing gears for wind turbines and solar power systems.

- Precision gears enable the effective conversion of energy, optimizing the performance of these sustainable technologies.

5. Industrial Manufacturing: Versatility in Gear Production

- CNC gear hobbing machines cater to the diverse needs of industrial manufacturing, providing gears for conveyor systems, industrial robots, and more.

- Customization options allow for the production of gears tailored to specific machinery requirements.

6. Medical Equipment: Precision in Medical Device Manufacturing

- CNC gear hobbing ensures the production of precision gears used in medical devices such as diagnostic equipment and robotic-assisted surgery systems.

- Consistency and accuracy are vital in medical applications, and CNC gear hobbing meets these standards.

7. Consumer Electronics: Compact Gears for Everyday Devices

- The production of small, intricate gears for consumer electronics like cameras and printers is achieved through CNC gear hobbing.

- Compact yet high-precision gears contribute to the functionality of these devices.

8. Innovations in Technology: Advancements in Gear Manufacturing

- CNC gear hobbing machines continue to evolve with technological advancements, incorporating features like multi-axis machining for increased efficiency.

- Innovations in software and automation enhance the overall capabilities of these machines.

From propelling vehicles to powering industrial machinery and contributing to sustainable energy solutions, CNC gear hobbing machines are the unsung heroes of precision engineering. Their applications span across diverse industries, showcasing the versatility and indispensable nature of these machines in shaping the mechanical components that drive our modern world.

No comments:

Post a Comment